63 three years of use and abuse will take its toll on the sheet metal of any car. Rain, rocks, road debris, sun and time all combine to tear down protective coverings and let the rust begin. For this car, I have had to cut out and replace pieces of the floor board, cargo door, firewall, and body panel to make this car rust free. This is one of the front fenders. The fenders have a brace on the inside for a bolt to hold them in place. In this area water from rain gathers and sits trapped between the brace and fenders causing rust. It is a common rust area on these cars.

Started prepping for paint, saw a bubble in the paint. Started sanding and found this beauty of partial rear end engineering. Kids, don’t do this at home. Body filler is to skim the surface , not create missing sheet metal. I am a hobbyist, not a professional – yet i know if you find yourself mixing several batches of filler, or having to throw the the filler at the repair to ensure it is packed in… you should have done a patch.

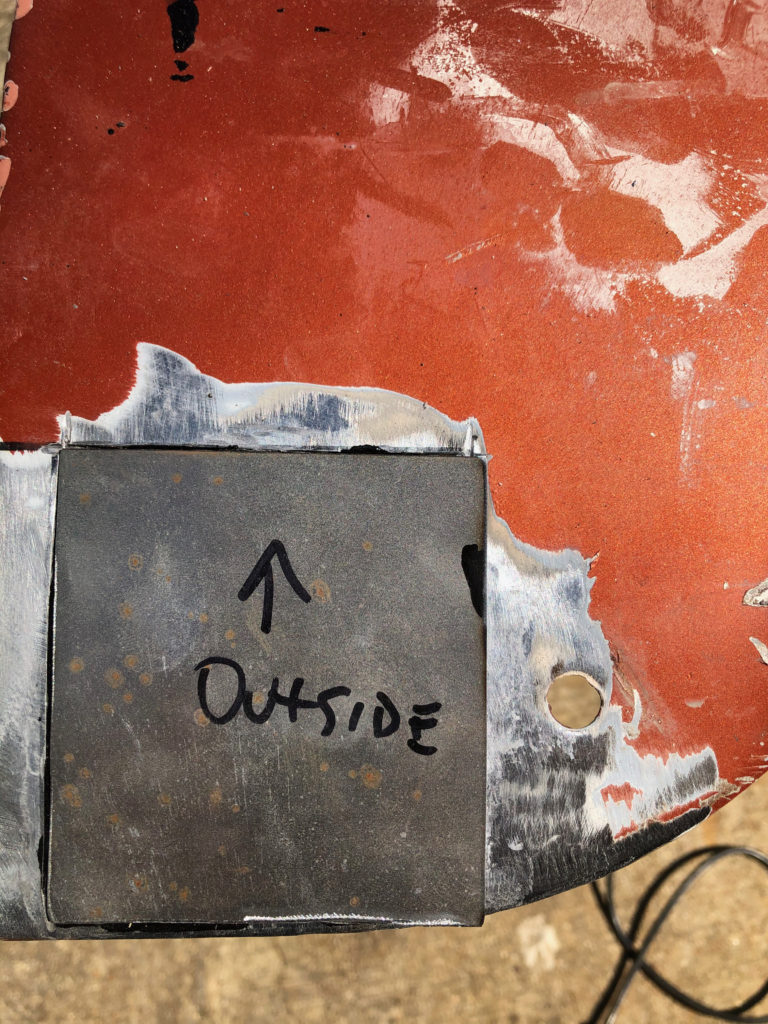

To fix, I started by sanding around the area to find good metal to weld to. If you try to weld to rusty metal, it will dissolve and blow holes in the fender. Not good. Then I marked the area to cut. Using a cut off tool, cut out the square. Squares are easier to cut, and easier to fit.

It looks terrible back there, but we can clean it up. First, sand away the top layer of the rust, then cover with POR 15 metal etch. It will convert the rust to black metal.

Then cover in POR 15. I cover the back side of the piece going in as well, i grind back a thin edge to sheet metal for welding to protect the weld. Also, i let this dry over night -finished next morning. There is plenty of other work to do .

Transfer the cut out piece to cardboard.

Fit cardboard exactly.

Transfer to sheet metal.

Cut out replacement piece. I had left overs from floor boards I had bought, used them to cut the patch out.

Fit exactly to the hole, just a sliver between all 4 sides. I also curved slightly to fit the fender curve by hand. Requires a little trimming with the grinder.

I held in place with magnets, spot welded a few places. Using body hammers, tapped it into place around the square , spot welding as I went.

With sheet metal and MIG welding, you have to repeatedly spot weld until its filled in all the way around the patch. Welding a continuous line would warp the metal.

Once filled in all the way, grind down smooth.

Body SKIM to even out the area for paint.

Sand.

Ready for paint!